Custom Wiring Harness Manufacturer - How to Select the Right one ?

Custom Wiring Harness Manufacturer

Custom Wiring harness manufacturers are generally involved in the processes of the manufacturing custom wire harness that is intended for an application.

Finding perfect custom wiring harness manufacturers/ companies can be a hurdle when you want to achieve success for your medical device. Do you want to outsource the wiring/cable harness assembly requirements that can be of value to your medical equipment?

Put in your extra time and effort in researching the best companies for your medical devices. Settling with a firm without proper research can greatly impact your business, time and money.

So, Who makes the best custom wiring harness ?

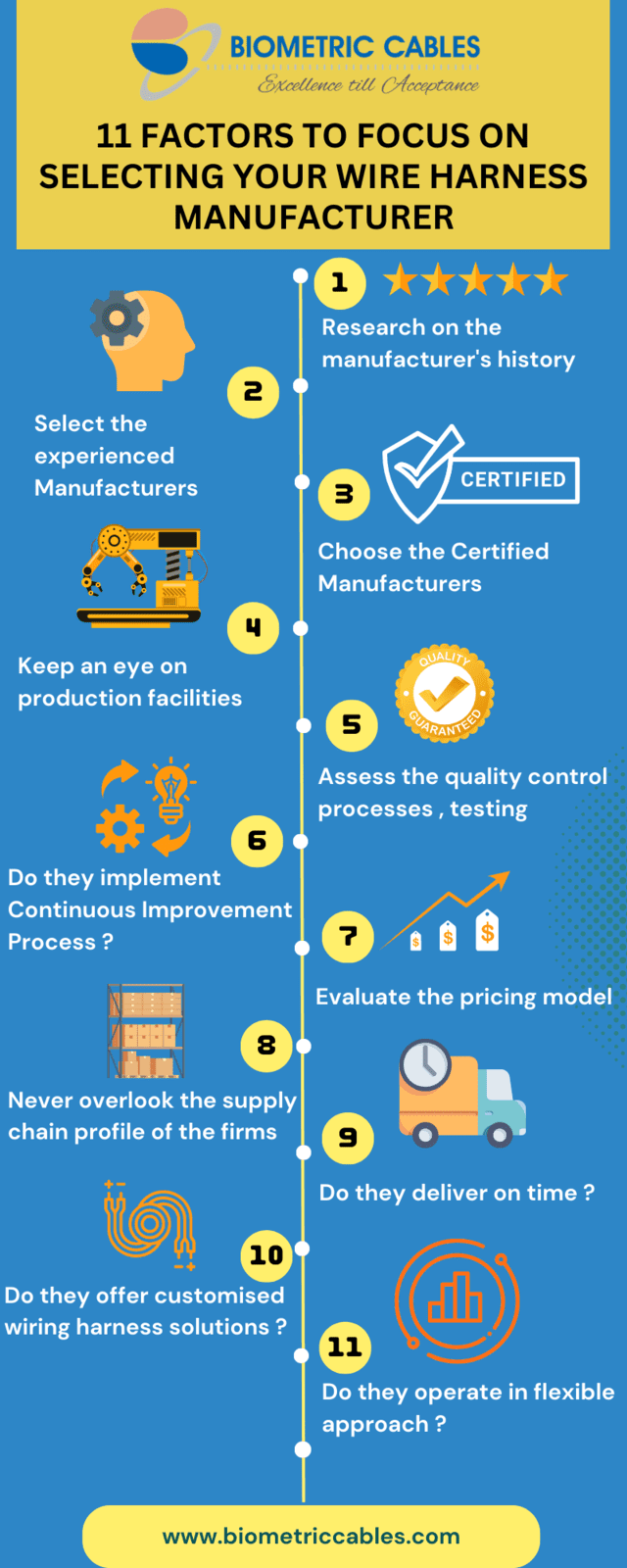

Here’s a set of pointers/ factors to be focused upon while routing yourself to the best custom wiring harness companies.

1.Have a peak into the custom wiring harness manufacturer’s history

It is certainly crucial to get associated with experienced companies to get professional work done on your devices. It might be tempting to believe the experience profile claimed by them. Don’t fall for their bait. Although they deem themselves as experienced wiring/cable harness manufacturing partners, it is extremely important to research them on their online ratings, reviews, and customer testimonials and even, maybe check on their client references before we jump in.

Checking on their past client's portfolio could help you to decide if they would be the right fit. Determining the product class category dealt in the wiring harness companies is of para importance. Similarly, determining whether the manufacturer has been positioned in manufacturing full-fledged wiring/ cable harness medical equipment or semi-developed products is ascertained to know.

The firms that have proven longevity down the years will provide an extra sense of assurance in the following aspects such as best manufacturing practices and processes to attain quality medical equipment.

2. Proven track records of expertise

Although It may appear enticing to work with a less experienced wiring/cable harness manufacturer for a lower cost, however, operating with an exceptional company can make a difference for your medical equipment.

Researching the types of wiring/ cable harnesses that the firm uses and the skill set levels in the medical device industry is of paramount importance. Besides that, based on the experience in the industry, it is necessary to find out the level of IPC certification held by the manufacturer and its employees. For instance, IPC offers 3 levels of certifications as Certified Standards Expert (CSE), Certified IPC Trainer (CIT) and Certified IPC Specialist (CIS).

Some of the wire harness pre and post-production processes might either be automated or semi-automated. For better clarity, You will also need to know from them whether the manufacturing processes would be automated or semi-automated or manually assembled. Keen attention should be paid to the proven track record of the manufacturer when it comes to the manual hand-wire harness assembly job.

It is necessary to evaluate their expertise level on various dimensions, likely wire harness design and engineering as it does have a huge effect on the functionality and quality of your medical equipment. Based upon the Mckinsey report, due to the low quality of medical devices, there have been various patient disability, death and hospitalization cases being reported that are likely to double quickly as the rising growth of the medical device industry.

The proficiency of the personnel staff, employees and inspection personnel should be checked in the objective evidence records which provide information on the respective job function training, work experi

3. Certifications do matter

Determine the custom wiring harness manufacturing partners who comply with the standards and regulatory requirements of the medical device industry. These manufacturing companies should be able to furnish the required certifications in alignment with harness manufacture. Moreover, select the firms which possess additional certifications that affirm their capabilities in achieving quality medical equipment based upon the customer requirements as per the international standards. A few such certifications to be sought out in the medical device industry are

ISO Standard: International Standard for Quality Management Systems in Businesses or Organizations

IEC standards: International Electrotechnical Commission for all electrical, electronic and associated technologies

IPC J-STD-001: Industry specification for electrical and electronic assemblies issued by IPC

IPC WHMA-A-620D: Standard that proposes Wiring / Cable harness manufacturing requirements and acceptance

4. Having a check on their production facilities

It is essential to consider a manufacturing company that has the capabilities of running a dedicated expert team for wiring harness design, engineering and production, and assembly according to the required specifications. Alternatively, the size and capacity of the manufacturing plant and workforce matter too.

Companies with large-sized plants tend to have larger, more experienced workforces compared to smaller companies. However, For smaller batches of medical wiring/cable harnesses, smaller to medium companies can be approached. Generally, larger companies do not accept smaller order requirements as they don’t focus on manufacturing small, limited batches.

On the contrary, selecting a company that specializes in both manufacturing small and large volumes of batches can be of value when you tend to face both requirement scenarios.

Ensure that the team of professional engineers do exist in the firms can guide you on how the harness is utilized in your medical application.

Check on the following :

1. Time duration involved in the wire harness design, the prototype and the final medical application.

3. Have they manufactured any similar types of harnesses for the same type of applications in the previous projects?

4. Do they implement processes that exhibit repeatability and volume which directly indicates the reliability of the wiring harness?

5. Quality management processes involved during the design, and manufacturing

5. Assessment of quality control processes and testing

Choose the custom wiring harness companies which strictly implement various medical quality assurance techniques such as ROHS, Statistical Process Control, PFMEA (Process Failure Mode and Effects Analysis ), Control Measures and Acceptance Criteria, Kaizen, 5S, Total Productive Maintenance, and Measurement System Analysis.

Needless to mention, opt for firms who not only perform extensive testing on the final medical device product but also at every wire harness stage like wire cutting, layout, stripping, crimping, soldering, welding processes etc. Some of the commonly used testing methods are Pull Testers for Crimping, pull testers for Soldering, Magnifiers for assembly inspection, hv testers, and Preprogrammed testers.

Ensure that they have the essential testing equipment such as pre-programmed tester/boards. The test boards are programmed according to the electrical specifications of the intended medical application.

Associating with wire harness businesses who conduct extra, detailed and rigorous quality checks contributes to further advantages to your medical device. Choose the ones that can exceed the quality requirements.

According to the report, A rise in medical device recall events was found to be at 8.8% in 2022 when compared to the year 2021. Similarly, based on the report, in Q2 2022, the medical device recalls soar by a rate of 11% in Europe compared to the previous quarter Q1.

6. Do the custom wiring harness manufacturers implement and practice Continuous Improvement Processes?

Before collaborating with any company, be sure that apart from meeting the industry standards and requirements, they should also exceed the quality requirements by aiming to continuously enhance the harness processes, services and products. For instance, implementation of the six sigma strategies such as DFMEA ( Design Failure Mode and Effective Analysis ), PFMEA ( Process Failure Mode and Effects Analysis), and maintenance of risk assessment file aids in the identification of risks involved in the wiring/ cable harnesses.

According to the Mckinsey report, few medical device manufacturing companies have utilized Quality Function Deployment (QFD) for accurately capturing their crucial requirements and needs. The report also cites that lack of risk assessment tools and negligence of non-updating the feedback frequently are some of the issues encountered in many manufacturing firms.

7. Evaluation of the Pricing model:

It is vital to check the pricing factor of the wire and its components associated with the wiring/cable harness assembly. Don’t settle down with ones who offer false promises and entice you with offer deals. Beware of such immoral companies whose manufacturing job ultimately leads to subpar medical equipment.

It has been reported by WHO that in the year 2010, a rough estimated 8% of medical equipment in circulation are regarded to be counterfeit and fake.

Selecting the manufacturing firms that provide the products at the lowest price can reflect in the quality of the final product. On the other hand, it is the best choice to work with those who can offer exceptional quality wire harnesses at an equitable fair price which works for both sides.

8. Supply Chain Management profile

Never overlook the supply chain management of the custom wiring harness manufacturing firm as it greatly impacts the manufacturing process of your wire harness assembly. It is necessary to keep an eye on the outsourcing capabilities of the companies on whether they can effectively outsource quality components on time. They are supposed to incorporate pre-planning processes and inventory tracking and management to eliminate last-minute obstacles.

Do you want a production downtime generated due to a delay in material delivery? Evaluation of their supplier vendor network and their committed timelines is a must. A delay in the supply of the wires cables from the vendor network can greatly impact various factors such as marketing of medical equipment, and halting the process of design, production and assembly.

Find out whether the manufacturing companies are on good terms with their suppliers. Conversely, It is crucial to check whether they source quality materials from the suppliers/vendors as eventually, bad quality materials can affect the outcome of your medical device.

9. Timely deliverables

The harness manufacturer should possess the effective and necessary ways/means to deliver the wiring cable harness devices on time. In the event of obstacles and hurdles that they go through, they should be transparent enough to communicate the delays as soon as possible to reduce your business inconvenience at the slightest level. The reliability and validation and calibration of machines and processes are essential in achieving the best possible operational efficiency which greatly affects the timely delivery.

10. Do they offer Customised Wiring Harness solutions ?

Joining hands with customised wiring harness manufacturers can offer you many benefits based on your medical application. They can provide many options such as custom labelling, four-colour ink stamping, lacing, custom colours etc depending on the nature of your requirement. Look for companies that possess custom in-house instruments, and several computer-aided design software (Autocad, Solid Works, Orcad, Prototyping etc) that tailors to your customised requirements.

11. Do the companies operate flexibly?

Ensure that your companies can function in a flexible approach whenever you are dissatisfied with certain aspects of design and prototyping. An exceptional firm would accept your feedback to attain a quality medical device whereas a low-quality harness manufacturer would not move along with your suggestions. It is important to lean on a custom wire harness manufacturing firm that offers a consultative discussion and approach through the journey. Startups who are looking for genuine manufacturers should tie up with those that function in a consultative approach.