Medical Cable Assemblies

Medical Cable Assemblies

Biometric Cables manufactures various custom medical cable assemblies for different medical applications depending upon the customer's intended requirements. We specialise in manufacturing high quality cable assemblies that aligns to the unique needs of healthcare industry, by offering reliable performance in utmost challenging circumstances. We ensure that each cable assembly is built to the demanding standards with consistent performance and precise tolerance.

We implement robust quality systems that are compliant and rigorously audited by our OEM customers. Through our 18 years of invested journey in manufacturing medical cables, we provide a wide range of medical wiring / cable assemblies capabilities. Our capabilities widely comprises of medical device design , development , medical quality assurance , and wiring harness / cable manufacturing and assembly process.

Medical Cable Assembly Solutions

With our unparalleled range of technologies, Biometric Cables aims at meeting your cable assembly requirements right from Design phase involving custom in house instruments, Design Failure Mode and Effective Analysis (DFMEA) and Rapid Prototyping. Our experienced team of engineers and technicians plays an indispensable role in designing and manufacturing the medical cables which meets the specific needs. BMC's workforce has been trained to be as certified IPC Specialists. Our state of art manufacturing facilities possess the in house ( from wiring diagrams till testing process) capability of manufacturing cables that meets the International Standards.

Without proper testing and measurements, the effectiveness and safety of the medical device cables could be compromised by risking the patient's lives. The quality of the cable assembly is ensured via medical quality assurance, quality control and rigorous testing methods. The extensive range of Biometric Cables' testing methods prepares for a high quality cable assemblies from design till production and testing phase. The medical wiring harnesses are manufactured to meet the requirements of medical regulatory affairs such as biocompatibility, ISO, ANSI/ AAMI, IPC Standards etc. The custom cable assemblies offered by us are designed to be of greater strength, and flexible to handle.

We offer a mix of competitive cable solutions for low orders and as well as low medium volume assembly projects. BMC implements manufacturing processes and tooling that ensures volume and repeatability , therefore contributing to reliable medical cable assemblies. We operate in a consultative approach with our Original Equipment Manufacturers partners to the fullest throughout the journey. Do you have any cable assembly in mind that needs to be designed or redesigned for your medical device ?

MEDICAL DEVICE DESIGN

- Solid Works, Autocad, Orcad

- Custom in house Instruments

- Design History Files

- DFMEA

- Rapid Prototyping

- Benchmarking

QUALITY ASSURANCE

- ROHS & REACH

- PFMEA (Risk Analysis)

- Control Measures, Acceptance Criteria

- Test Labs

- Machine and Process Validation

- QMS as per ISO 13845

- Measurement System Analysis

- Run at Rate

- Statistical Process Control

- IPC J-STD-001 & IPC WHMA-A-620D Class 2 & 3 level acceptance

- APQP

- G8D for customer complaints

- Scar for Suppliers

- Kaizen

- 5S

- Total Productive Maintenance

- Digital Magnification Aid For Inspection

MEDICAL DEVICE MANUFACTURING PROCESSES

- Closed loop injection moulding

- Vertical Injection Moulding

- Horizontal Injection Moulding

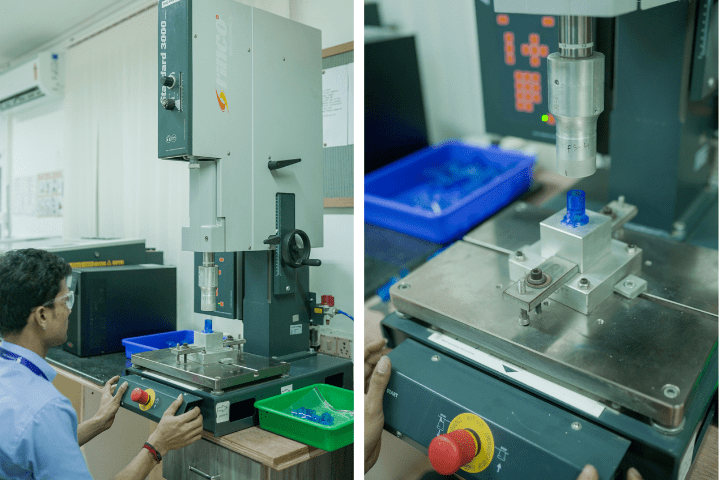

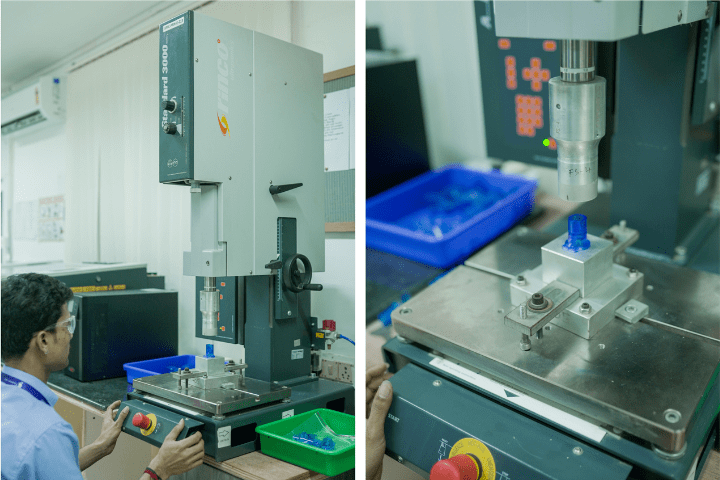

- Ultrasonic Welding

- Laser Cutting

- Semi automatic Cable Cutting

- Semi Automatic Cable Stripping

- Semi Automatic Cable Crimping

- DIP Soldering

- Toggle Clamping & Sealing

- Shield Unwinding

- Packing Machines

- People Expertise

- Preheat ovens

- Pad Printing

- Semiautomatic moulding machine

- EO Sterilisation

- Restricted ESD free production process

REGULATORY AFFAIRS

- IEC,ISO, ANSI/AAMI,

- IPC standard compliance

- ISO,CE,UL,IPC certifications,QMS,21 CFR part 820

- Biocompatibility , Testing certification

- EUDAMED

- CDSCO registered

QUALITY CONTROL

- Customised Jigs, Fixtures & Machines,

- Measuring Instruments,

- SAP,

- Go NO Go Gauges,

- Leak Testers,

- Universal Cable Testers,

- Ventilators,

- HV Testers,

- Semi- Automatic Pull Testers

CONSULTATIVE APPROACH

- 17+ Years in Business

- Experts in products, We manufacture 3500+ products

- Experts in process, We have expertise in 10+ Value chains

- 10+ OEM clients

- Export to 15+ countries

Medical Cable Assemblies

Medical Cable Assemblies

Biometric Cables manufactures various custom medical cable assemblies for different medical applications depending upon the customer's intended requirements. We specialise in manufacturing high quality cable assemblies that aligns to the unique needs of healthcare industry, by offering reliable performance in utmost challenging circumstances. We ensure that each cable assembly is built to the demanding standards with consistent performance and precise tolerance.

We implement robust quality systems that are compliant and rigorously audited by our OEM customers. Through our 18 years of invested journey in manufacturing medical cables, we provide a wide range of medical wiring / cable assemblies capabilities. Our capabilities widely comprises of medical device design , development , medical quality assurance , and wiring harness / cable manufacturing and assembly process.

Medical Cable Assembly Solution

With our unparalleled range of technologies, Biometric Cables aims at meeting your cable assembly requirements right from Design phase involving custom in house instruments, Design Failure Mode and Effective Analysis (DFMEA) and Rapid Prototyping. Our experienced team of engineers and technicians plays an indispensable role in designing and manufacturing the medical cables which meets the specific needs. BMC's workforce has been trained to be as certified IPC Specialists. Our state of art manufacturing facilities possess the in house ( from wiring diagrams till testing process) capability of manufacturing cables that meets the International Standards.

Without proper testing and measurements, the effectiveness and safety of the medical device cables could be compromised by risking the patient's lives. The quality of the cable assembly is ensured via medical quality assurance, quality control and rigorous testing methods. The extensive range of Biometric Cables' testing methods prepares for a high quality cable assemblies from design till production and testing phase. The medical wiring harnesses are manufactured to meet the requirements of medical regulatory affairs such as biocompatibility, ISO , ANSI/ AAMI, IPC Standards etc. The custom cable assemblies offered by us are designed to be of greater strength, and flexible to handle.

We offer a mix of competitive cable solutions for low orders and as well as low medium volume assembly projects. BMC implements manufacturing processes and tooling that ensures volume and repeatability , therefore contributing to reliable medical cable assemblies. We operate in a consultative approach with our Original Equipment Manufacturers partners to the fullest throughout the journey. Do you have any cable assembly in mind that needs to be designed or redesigned for your medical device ?

MEDICAL DEVICE DESIGN

MEDICAL DEVICE DESIGN

- Solid Works, Autocad, Orcad

- Custom in house instruments

- Design History Files

- DFMEA

- Rapid Prototyping

- Benchmarking

QUALITY ASSURANCE

QUALITY ASSURANCE

- ROHS & REACH

- PFMEA (Risk Analysis)

- Control Measures, Acceptance Criteria

- Test Labs

- Machine and Process Validation

- QMS as per ISO 13845

- Measurement System Analysis

- Run at Rate

- Statistical Process Control

- IPC J-STD-001 & IPC WHMA-A-620D Class 2 & 3 level acceptance

- APQP

- G8D for customer complaints

- Scar for Suppliers

- Kaizen

- 5S

- Total Productive Maintenance

- Digital Magnification Aid For Inspection

MEDICAL DEVICE MANUFACTURING PROCESSES

MEDICAL DEVICE MANUFACTURING PROCESSES

- Closed loop injection moulding

- Vertical Injection Moulding

- Horizontal Injection Moulding

- Ultrasonic Welding

- Laser Cutting

- Semi automatic Cable Cutting

- Semi Automatic Cable Stripping

- Semi Automatic Cable Crimping

- DIP Soldering

- Toggle Clamping & Sealing

- Shield Unwinding

- Packing Machines

- People Expertise

- Preheat ovens

- Pad Printing

- Semiautomatic moulding machine

- EO Sterilisation

- Restricted ESD free production process

REGULATORY AFFAIRS

REGULATORY AFFAIRS

- IEC,ISO, ANSI/AAMI,

- IPC standard compliance

- ISO,CE,UL,IPC certifications,QMS,21 CFR part 820

- Biocompatibility , Testing certification

- EUDAMED

- CDSCO registered

QUALITY CONTROL

QUALITY CONTROL

- Customised Jigs, Fixtures & Machines,

- Measuring Instruments,

- SAP,

- Go NO Go Gauges,

- Leak Testers,

- Universal Cable Testers,

- Ventilators,

- HV Testers,

- Semi- Automatic Pull Testers

CONSULTATIVE APPROACH

CONSULTATIVE APPROACH

- 17+ Years in Business

- Experts in products, We manufacture 3500+ products

- Experts in process, We have expertise in 10+ Value chains

- 10+ OEM clients

- Export to 15+ countries